Digital Lutherie

luthier - a craftsman who makes stringed instruments (such as lutes or guitars)

lutherie - the art practiced by luthiers

-----------------

What is Digital Lutherie?

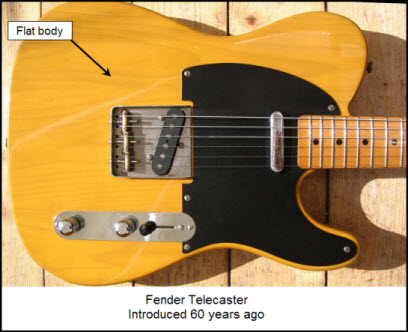

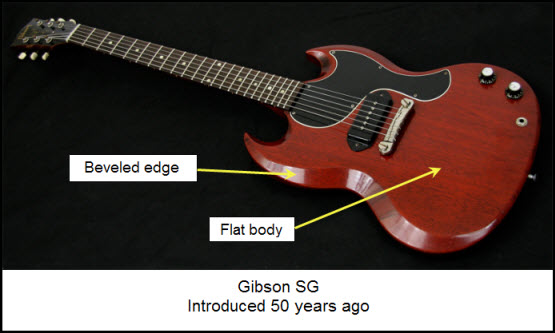

Digital lutherie is the art of using modern CAD/CAM technology to design and fabricate modern-looking, organic guitars - guitars that transcend today's typical, flat, two-dimensional, 1950s look.

Old-school guitar builders today are limited to two-dimensional designs. They start with a flat plank of wood, and it pretty much stays that way. They often design "on the fly", with chisels, saws and sandpaper.

Digital lutherie is different. All of the designing and trial-and-error experimentation takes place in the digital realm. No trees are hurt during the process. If the design doesn't look quite right, it can be easily tweaked in the software - right on the computer screen - and not with wood-putty and files... or throwing the piece away and starting with another chunk of wood.

In digital lutherie, the final design geometry is downloaded and machined on a programmable, computer controlled router. These CNC routers (computer numerically controlled) faithfully and effortlessly machine out the surfaces and geometry created in the CAD program (computer aided design). They are extremely precise, don't get tired, and have no problem making multiple copies.

Consequently, the overall process frees the guitar-designer from the age-old tethers of working only in two dimensions, and thereby opens the door to much more organic, natural looking designs. KOZM guitars naturally conform to the body of the player. They strive to be as non-flat, flowing and evolutionary as the music played by their owners.

The Design Process:

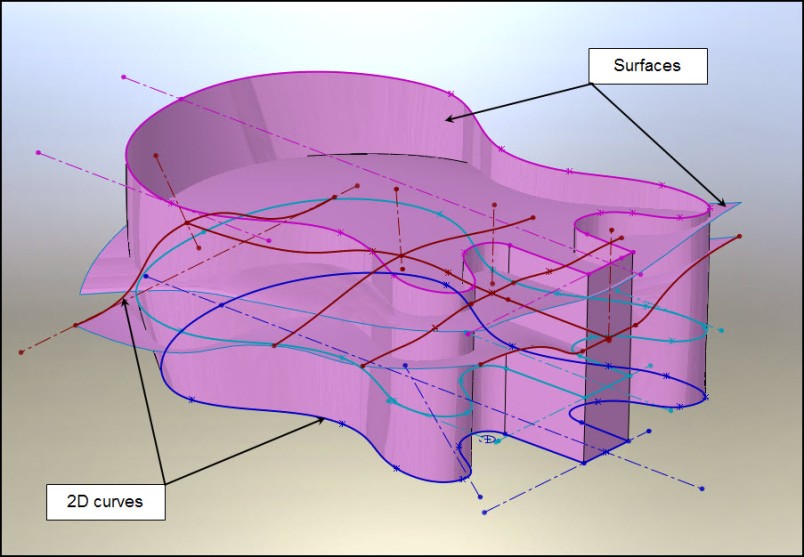

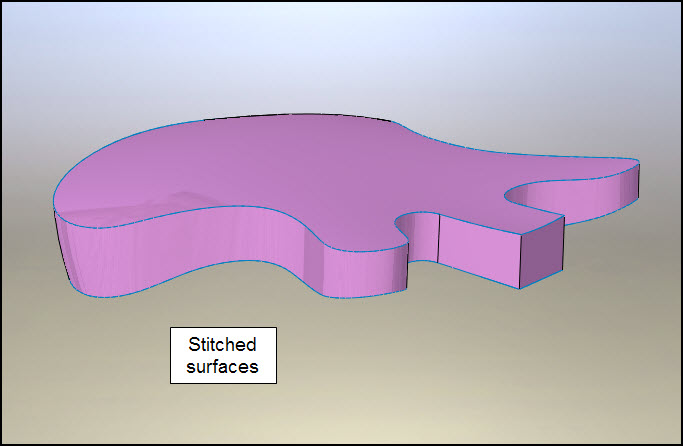

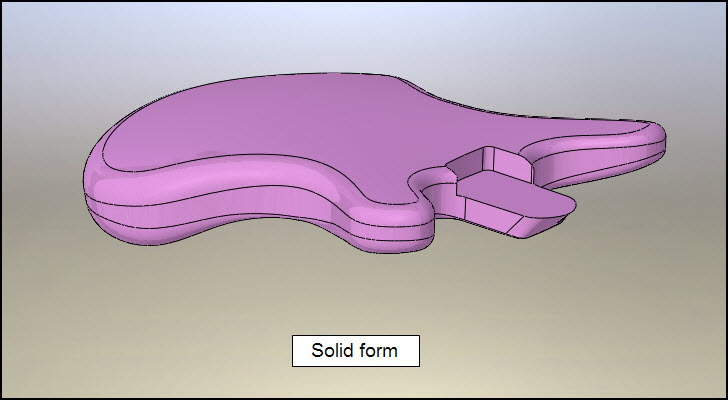

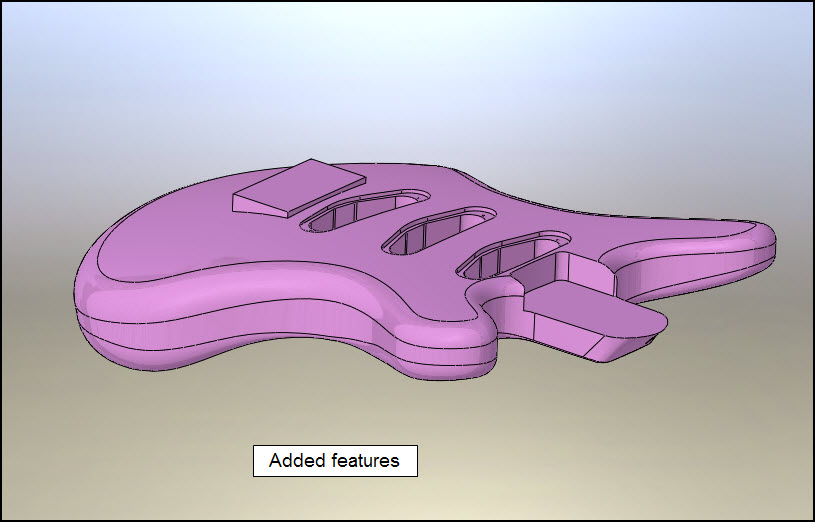

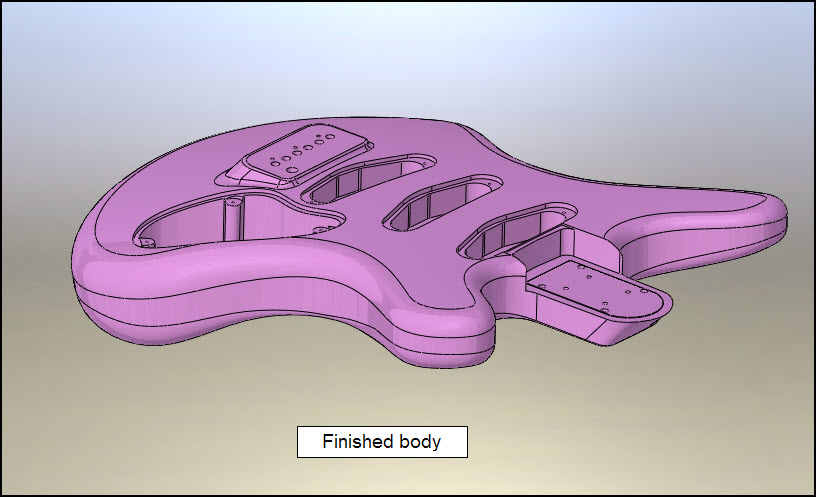

Much like old-school guitar builders, my inspiration for a new design starts with an idea in my head. I then begin "sketching out" this idea in my CAD program. It starts with 2D curves and splines that are either projected or extruded through digital-space, or are guided by other curves I've created. These swept curves generate complex surfaces. These surfaces then combine, or are "stitched" to other surfaces, to eventually create a closed, solid body. Finally, all the pockets and mounting holes are added that will accommodate the pickups, neck and other hardware. The following set of images describes the general process.

The Fabrication Process:

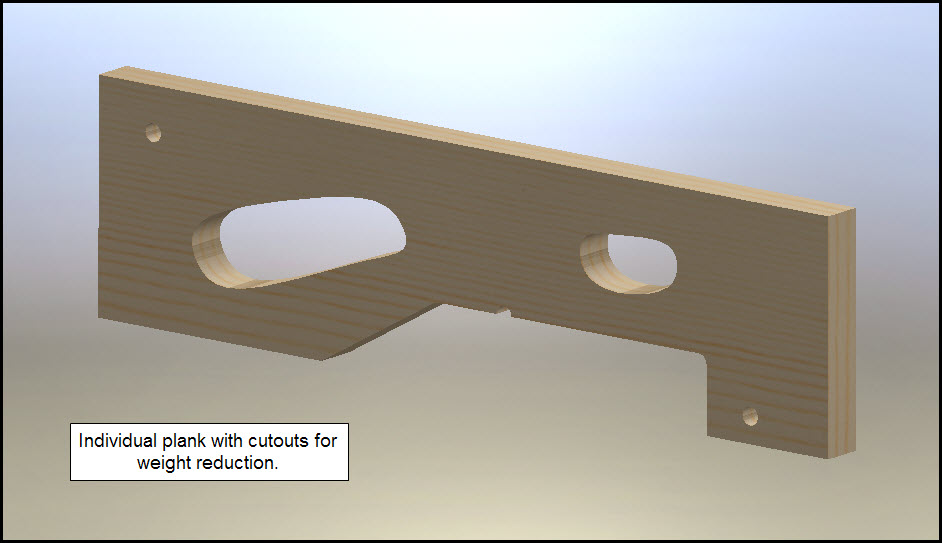

A standard Fender Stratocaster is less than 2 inches thick. My designs are close to 4 inches from front to back. Instead of trying to find a single block of wood that's big enough, I basically "slice up" my body into individual, thin planks. This allows me to use wood from younger trees, and thereby spare the old-growth timber. It also allows me to use different types of wood across the body, to attain different tonal and structural characteristics. Finally, it allows me to add "chamber cut-outs" to each plank.

I then glue-up all of the individual planks into one, large block. After the clamps are removed and the glue has cured, the block then gets clamped to my router table, and is machined.

Front side of guitar body after first machining operation.

Front of guitar after further machining.

Body flipped over for machining on back side. (Click on YouTube link below for a more details about flipping the body over.)

After final machining operation and light sanding.

If it's a new design, the guitar is then built up and I finally get to play it!

This is an MT-3. You can see the maple "spine", followed by a plank of walnut on either side, and finally alder.

Link to video describing the "flipping over" process.